Chicken slaughtering and processing is big business in Arkansas, home to Tyson Foods—the world’s top company in this highly consolidated industry.

Union of Concerned Scientists (UCS) analysis shows that many Arkansas farmers, workers, and communities suffer from Tyson’s monopoly-like power in the state. Chicken farmers are paid through a complex and competitive contract system that gives Tyson immense power over their operations. As this system has developed over the past several decades, thousands of farms have gone out of business or been forced to consolidate.

Meanwhile, Tyson’s processing plants endanger their workers and outsource the management of billions of pounds of chicken waste, some of which contaminates waterways and threatens public health, particularly in Arkansas’s Hispanic and Native American communities. Equitable, science-based federal and state policies are needed to curb Tyson’s power, return fairness to the industry, protect workers, and ensure clean air and water for communities.

Tyson Spells Trouble for Arkansas

If you have ever purchased or eaten chicken, beef, or pork, chances are that it came from one of 177 slaughtering and processing plants owned by Tyson Foods Inc. across 21 US states. Operating under this name and others—including Ball Park, Hillshire Farm, and Jimmy Dean—Tyson Foods is the nation’s largest meat and poultry company and the most dominant in chicken, processing 2.3 billion birds in 2020 alone (Tyson, n.d.). Tyson accounts for the largest single share of all chicken slaughtering and processing nationwide (M. Hendrickson, Howard, and Constance 2017). And with more than $42 billion in annual revenue, 139,000 US employees, and a rank of 73 on the 2019 Fortune 500 list, Tyson stands out as a big player not just in chicken but also in corporate America (Tyson 2019; Fortune 2021).

Established in 1935, Tyson quickly rose to the top of the poultry processing industry after the 1920s federal government push to address antitrust issues in meatpacking began to subside. It rose to the top using a uniquely aggressive approach to strategic acquisition to grow its operations (Frantz 1994). In 2018, for example, Tyson bought Keystone Foods—supplier of McDonald’s Chicken McNuggets—for $2.3 billion (Narayanan 2018). The company’s list of acquisitions stretches long and goes back decades (see the full history over the past three decades in Table 1).

But Tyson also gained significant competitive advantages by influencing politicians and policy in its home state of Arkansas. In the late 1970s, Tyson began to develop a close relationship with then-governor Bill Clinton (Fritz 1994). This political lobbying won the company tax breaks and other financial benefits that allowed it to flourish in the 1990s (Maraniss and Weisskopf 1992). In the 2000s, it contributed hundreds of thousands of dollars to candidates and committees engaged in state politics, according to publicly available contribution data (NIMP and TCFI 2021). Tyson continues to have power over its home state’s politicians. In 2020, for example, the mayor of Springdale—the city in which Tyson has its global headquarters—worked hand in hand with Tyson government affairs and public relations staff to respond to national media inquiries about COVID-19 cases in the Springdale region at a time when the area led the nation in virus case growth (Paschal 2021a).

A key economic player in Arkansas, Tyson is the third-largest employer statewide, operating nearly half of all slaughtering and processing plants (Hennigan, Zimmardi, and Sanchez-Smith 2021; Tyson 2018). Moreover, Arkansas is not just the heart of Tyson’s global operations, but also a major center of US chicken farming, slaughtering, and processing. Data from the most recent US Census Bureau Economic Census reports $8.1 billion in sales from Arkansas poultry processors in 2017 (US Census Bureau 2017a). The state also ranks first in number of chicken slaughtering and processing plants (FSIS 2021). Arkansas has the most meat chicken (also known as broilers) contract farms and ranks third for total broiler farm sales nationally, just behind Georgia and Alabama (USDA 2017). Given Arkansas’s rank in US chicken farming, slaughtering, and processing, the state is an important focal point for evaluating the market structure of the broiler farming and processing industry.

Our analysis, using well-established economic measures of concentration, found an alarming level of concentration in the Arkansas poultry slaughtering and processing industry. As this consolidation grew in the state, significant changes occurred in the agricultural sector. According to our analysis, Arkansas has lost nearly 50 percent of its broiler farmers since 1978, and its broiler farms are larger than ever before. We discuss how this consolidation and the geographic concentration of this industry likely hurt farmers, nearby communities, and poultry plant workers. Addressing these harms will require public policies based on sound science, equity, and the public interest. Using our findings, we recommend actions for federal and Arkansas policymakers.

Driving Forces behind Food System Consolidation

To understand why processing broilers became such big business for Tyson and its top competitors, one must understand the broader economic forces shaping our food system. Over time, the global food system has become dominated by ever-larger farms and food companies (Hendrickson 2015; Ferguson 2021; M. Hendrickson et al. 2001). One fundamental concept in economics explains much of this shift: economies of scale. For a company or business, if the average cost of producing goods—say, chickens or corn—on a per-unit basis decreases as production quantity increases, economists label that activity as exhibiting economies of scale (Boehm, Cash, and Drescher 2015).

A simplified example can help illustrate economies of scale in the agricultural sector. Imagine two farmers similar in all characteristics, except that one manages 100 acres and the other 1,000, who both need to purchase a tractor. If the cost of the tractor is divided by acres, the cost of the tractor will be, on average, lower for the farmer managing 1,000 acres. In turn, the farmer with lower average costs per acre will be able to compete more effectively in the marketplace because average production costs per acre are lower. Thus, economies of scale drive many parts of our food system toward larger and larger operations.

Past policies and politics have also played a key role in driving consolidation in the food system as a whole and in the broiler industry in particular. The cornerstone policy that ensures fair livestock markets is the Packers and Stockyards Act, enacted in 1921 to address rising consolidation and concentration in the meatpacking sector. However, the law was significantly diminished by the Reagan administration and US courts beginning in the 1980s (OCM 2016). As a consequence, consolidation and anticompetitive livestock markets reemerged in the 1990s and 2000s, and the 2008 Farm Bill included new provisions such as the birth of the Grain Inspection, Packers and Stockyards Administration (GIPSA) at the US Department of Agriculture (USDA 2017; OCM 2016).

Unfortunately, GIPSA was hamstrung from the beginning. Before any new GIPSA regulations could be implemented, Congress introduced language to annual federal agricultural appropriations legislation called the “GIPSA rider.” The rider essentially defunded much of GIPSA’s functions, preventing it from carrying out its mission. Then, in 2018, the Trump administration dealt GIPSA another major blow. It consolidated the functions of GIPSA into the USDA’s Agricultural Marketing Service, which some advocates claimed created a conflict of interest (OCM 2018) given the Agricultural Marketing Service’s close ties with meat and poultry packers and other companies that buy products from farmers. Today, the consolidation and competition issues that plague livestock markets remain largely untouched by federal policy.

The Economics of Competition (or Lack Thereof)

Generally, economists agree that more competition is better for consumers and businesses (Bureau of Competition 2015), so consolidation in any industry is concerning from a policy and social welfare perspective. Problems arise when one or a few of the companies in a relatively uncompetitive market are able to influence others engaged in that market. In other words, in some markets these influential companies can act as price setters and exert market power, which allows them to dictate prices or output in a way that is beneficial to them, but not beneficial to other businesses or consumers.

In competitive markets, where there are many buyers and sellers of a good or service, individual companies or businesses cannot exert market power over prices or quantities sold. For example, in a highly competitive market, one company could raise the price of its good or service. Assuming other companies maintain their price levels and all other market conditions remain the same, buyers could—and probably would—simply buy the less expensive competitor’s product. In highly competitive markets, companies selling goods or services are considered “price takers” for this reason. This is why competition is good for businesses and consumers alike.

A monopoly is the most extreme example of a market with insufficient competition, and it occurs when there is just one company selling goods or services to many buyers. Similarly, when there is only one buying company in a market, economists call that a monopsony. True monopolies and monopsonies are uncommon in the real world, but when they do exist, economic theory dictates that prices and the quantity of output are distorted away from optimal levels. In a monopoly market structure, for example, monopolists tend to reduce output, which raises the prices for their goods or services.

More commonly, oligopolies or oligopsonies arise when just a few buyers or sellers operate in a market. In oligopolies and oligopsonies, the few companies operating in a market can more easily act as price setters by coordinating with each other to dictate prices and the quantity of goods and services they sell or buy. This coordination has real-world impacts. For example, it can affect how much companies will pay for supplies or inputs for their operations, how much they offer in worker wages, or how much they charge those who buy their products. In some cases, companies will establish formal, legal organizations—sometimes referred to as cartels—for coordination purposes (Jacquemin and Slade 1989). Outside of government-sanctioned agreements, companies can agree to coordinate prices or output on their own, which is considered price fixing and illegal under US law (USFTC 2013).

Price Fixing and Political Influence

Oligopolistic and oligopsonistic market structures have become more dominant in the food supply chain, especially in the livestock sector and in broiler production and processing. In the US broiler processing and slaughtering industry, economies of scale were documented as early as the 1970s (Ollinger, MacDonald, and Madison 2005) and, in part, contributed to substantial consolidation over the past half-century (Ollinger, MacDonald, and Madison 2000). As a consequence, just four companies slaughtered and processed 55 percent of all broilers in 2018 (Packers and Stockyard Program 2019), reflecting a level of concentration that could allow companies with the largest market share to coordinate their pricing and output levels (Sexton and Xia 2018; Saitone and Sexton 2017). While these national levels of concentration are concerning for buyers of chicken, it is more important to evaluate local or state levels of concentration in broiler markets, given that these supply chains are geographically concentrated. Consequently, evaluating concentration at a regional or state scale is more informative because it better reflects the actual market dynamics that farmers and workers encounter.

Numerous national lawsuits reveal how these companies have attempted to exploit the consolidated nature of these markets to manipulate pricing and output decisions to their benefit. In 2019, consumers, retailers, restaurants, and wholesalers filed a lawsuit accusing Tyson and other top US chicken processors of engaging in a price-fixing scheme that inflated chicken prices (Leonard 2021). Another suit accused Tyson of colluding with other poultry processors to depress wages for its largely immigrant workforce via secret meetings at a Florida hotel (Shanker and Mosendz 2019). Farmers also sued Koch Foods, Perdue Farms, and Tyson Foods for allegedly fixing prices on $30 billion of live meat chickens the companies purchased (Leonard 2016).

Coordination across a few dominant companies in an industry can also aid the ability of those companies to influence policy and regulation. For example, Tyson used its political clout in Arkansas in the early 1990s to reform workers’ compensation laws to reduce the costs the company incurred for worker injuries and deaths (Grabell 2015). More recently, in the early days of the COVID-19 pandemic in 2020, Tyson bought full-page ads in major state and national newspapers (including the Arkansas Democrat-Gazette) to warn that meat would disappear from US grocery shelves if its processing plants remained closed due to COVID-19 shutdown orders (Budryk 2020). Just two days later, President Trump signed an executive order pressuring meat and poultry slaughtering and processing plants to reopen despite the clear threat to workers (Boehm 2020a). Investigative journalists later discovered that meat and poultry industry lobbyists, who work for companies such as Tyson, had sent top USDA officials a draft document bearing many similarities to Trump’s executive order just one week prior (Grabell and Yeung 2020).

Complex Tyson Contracts Disempower Farmers

As Tyson and other top broiler processors bought out smaller companies and the industry consolidated, raising policy and social welfare concerns, another form of consolidation occurred. This consolidation—referred to as vertical integration—happens when a company purchases or acquires companies in its supply chain so it can have more control over all facets of production. Vertical integration has occurred in many parts of the food and agricultural system (Sexton and Xia 2018), including in broiler markets.

Broiler processors such as Tyson—referred to in industry parlance as integrators—own most of the supply chain, including the mills that process grain into feed, the hatcheries that produce broiler eggs and young breeding-stock chickens, the processing plants, and the plants that render and further process fats and other waste products (MacDonald 2014). What they do not own they contract out to independent farmers. In these contracts, independent farmers raise the breeding stock of broilers and the live market chickens, the latter of which are ultimately transported back to a processing plant owned by the integrator (MacDonald 2014).

Crucially, farmers who raise broilers for meat are not technically paid for the chickens they produce. Instead, they are paid for the labor they expend to grow chicks to market weight through prearranged contracts (MacDonald 2014). These contracts include provisions paying farmers through the so-called tournament system, in which farmers’ performance raising chickens is evaluated against other farmers who have contracts with the same integrator. Aptly named, the tournament system involves farmers competing against each other to earn the highest pay for their services (Levy and Vukina 2004). Some farmers have claimed that the tournament system is unfair, prompting the Obama administration to propose rules to provide farmers with more predictable pay, rules that were ultimately never implemented (Charles 2014).

The advantages and disadvantages of broiler industry vertical integration and the tournament system have been topics of debate in policy and advocacy circles. While we do not fully evaluate the advantages and disadvantages in this report, we describe these specific facets of the broiler market because they are important to understanding the markets in which broiler farmers engage. Further, these details make it clear that farmers are not selling live chickens to broiler integrators, and no market exists for broiler chickens per se.

Instead, broiler markets between contracted farmers and integrators/processors are defined by the buying and selling of labor and services. This distinction is crucial to understanding these markets and to understanding how consolidation and lack of competition among processors may affect farmers, workers, and communities where processing occurs in Arkansas and other states.

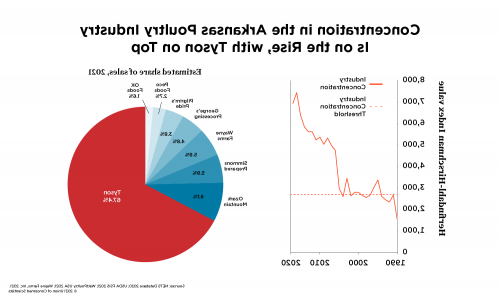

Note: See endnotes 1 and 2 for calculation details. Percentages do not add to 100 due to rounding. Non-integrator poultry processor sales for companies including B&R Meat Processing, Key's Family Butcher Shop, and Natural State Processing were not available and are not reflected in the above pie chart. However, these companies represent a very small share of total sales in the state.

Sources: NETS Database 2020; USDA FSIS 2021; WattPoultry USA 2021; Wayne Farms LLC 2021.

The High Degree of Consolidation and Concentration in Arkansas

Because Arkansas is one of the key states for poultry processing and the home of the industry’s top company, Tyson, it makes for an important case study of the industry.

First, we assess the historical and current degree of concentration in the market by calculating the Herfindahl-Hirschman Index (HHI), a quantitative indicator used by economists and regulators to evaluate the degree of competition in an industry or market and to determine whether a market is highly concentrated. Markets with an HHI value greater than 2,500 are considered highly concentrated and of policy or regulatory concern because of the potential for top companies to engage in coordination, uncompetitive pricing, or reduced output (Antitrust Division 2015). We calculated an annual HHI value for the Arkansas poultry processing industry from 1990 to 2017 (the most recent year for which these data were available at the time this report was written), using estimated sales data from the National Establishment Time Series (NETS) Database.1

Based on this analysis, we found an HHI value of 6,930 for the Arkansas poultry processing industry in 2017 (Figure 1). The HHI value has been above the Department of Justice Antitrust Division 2,500 threshold since 1994 and has increased through the mid-2000s. But after 2005, the HHI value sharply increased to the high level observed in 2017.

Further, we find that Tyson today is the dominant integrator in Arkansas’s poultry processing industry, and that the majority of poultry processing is conducted by just a handful of companies (Figure 1).

We estimate that:

- In 2021, Tyson accounted for 67 percent of the state’s poultry processing sales,2 a measure of its output, in dollars.

- Tyson’s estimated share of the market and the estimated shares of three other companies—Ozark Mountain Poultry (8 percent), Simmons Prepared Foods Inc. (6 percent), and Wayne Farms (6 percent)—account for 87 percent of all industry sales in the state.

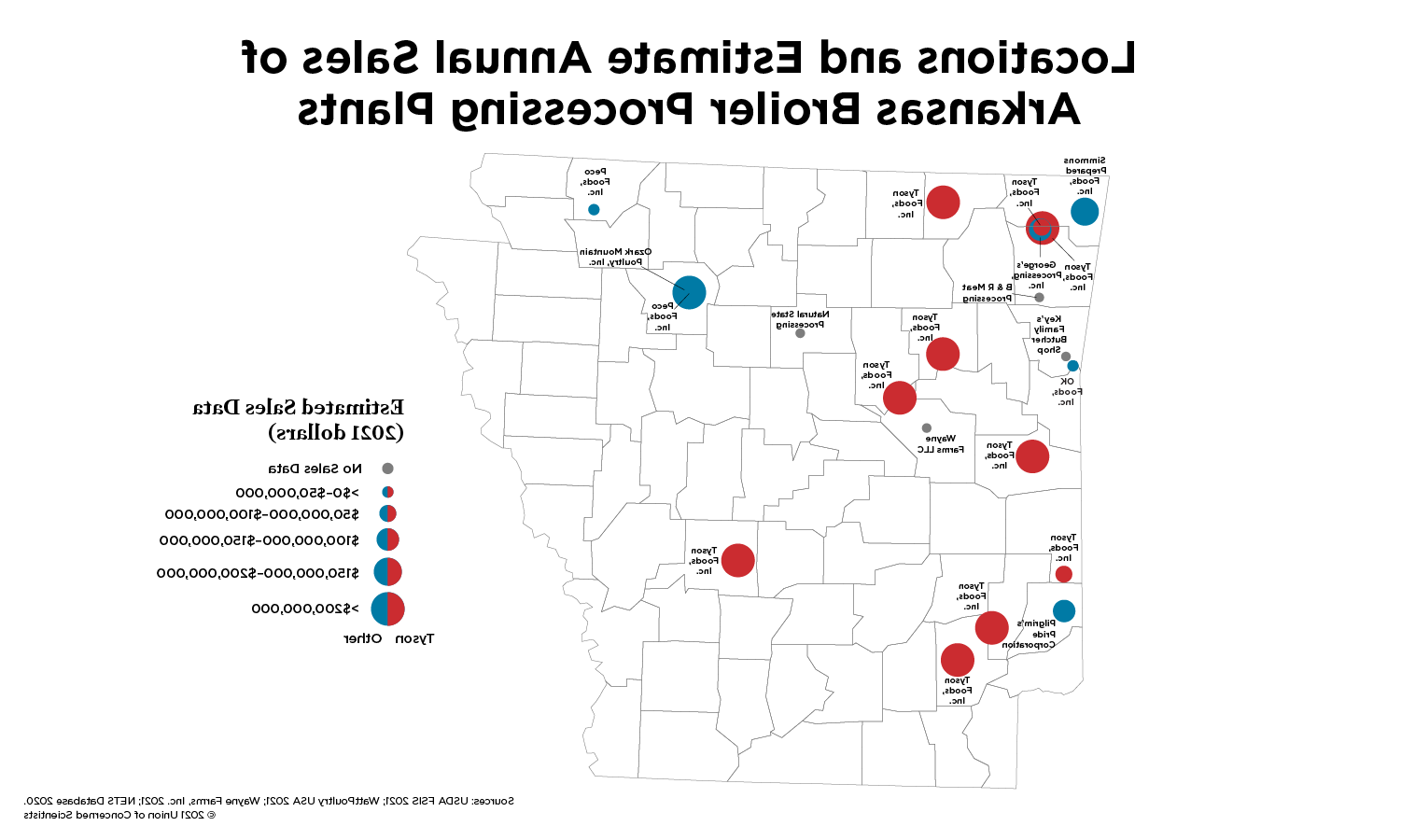

We drilled down further to understand the current level of consolidation in poultry processing at the county level in Arkansas, because the geographic distribution of integrators and broiler farms affects whether an integrator has the ability to exert market power over farms. Generally, if many integrator plants are clustered in one area or county near several broiler farms, these farmers have a relatively more competitive set of integrators with which they can choose to contract. Importantly, poultry supply chains are hyperlocal and geographically concentrated in the United States, wherein live chickens are trucked just 34 miles on average from farms to processing plants, minimizing the transportation costs and associated economic losses farmers may incur due to chicken injury or death during transit (MacDonald 2014). Consequently, this county-level analysis provides important information about whether integrators can exert market power over Arkansas broiler farmers.

For this county-level analysis, we calculated total poultry processing sales for each Arkansas county where poultry processing plants operated in 2021 (see endnote 2 for calculation details). Then we calculated the share of total sales for each distinct company operating in each of these counties, excluding plants that do not operate as integrators since no sales data for these companies were available, to understand the level of competition and concentration within each.

We found that:

- In 11 of 14 Arkansas counties with at least one integrator poultry processing plant in 2021, just one company accounted for 100 percent of estimated sales. In 7 of the 14 counties, Tyson was the one company controlling all sales.

- One company controls at least 58 percent of processing output in every Arkansas county that had a poultry plant in 2021.

- Figure 2 shows where these plants are located and their size in terms of sales.

The results from our analysis are concerning when considered in the context of a national study that found when broiler farmers had fewer than four processors in their area, integrator processors were able to exert market power over the prices paid to farmers for their services (MacDonald and Key 2012). Thus, our findings indicate that Arkansas broiler farmers may be facing the consequences of oligopsony or monopsony market power.

However, in interpreting these findings, it is important to note that our analysis has limitations. First, we evaluate changes over time in state-level concentration using the HHI and NETS sales data from 1990 to 2017, which are estimated using industry-average employee-to-sales ratios. These ratios assume that every establishment or company has the same sales per employee. While we did account for differences in employee-to-sales ratios across companies for the most recent year of sales data we evaluated to estimate market shares for top companies, we could not do this for all years evaluated in our examination of change over time in the HHI.

Second, for our evaluation of county-level concentration, we do not include integrator processing companies or farms that are near the borders of Arkansas. Third, we could not obtain data on the value of contract farmer services paid by Tyson and other poultry processors. Our analysis is based on the assumption that sales of processed poultry products serve as a proxy for the value of contract broiler farmer services paid for by poultry processors in the state. While our measures of concentration would ideally be based on contract grower service value purchased by integrators, to our knowledge, these datasets do not exist in aggregated form or are not publicly available.

Fourth, our analysis and the results presented here cannot be used to determine if Arkansas broiler integrators can exert market power over wholesalers, retailers, restaurants, or consumers, as the supply of processed chicken products in Arkansas includes imports from other states, even though some evidence does suggest that these companies exert oligopoly power, especially because the biggest processors and integrators (such as Tyson) sell multiple products such as beef and pork (Schroeter and Azzam 1990). Further, Arkansas-based processors also export their products to other states and into the national market, further complicating any analyses of market power that they may exert over consumers and buyers of their products.

However, our analysis does reveal that Tyson and other major processors and integrators likely are able to exert market power in the majority of the local markets in which they engage with Arkansas broiler farmers. Additional analyses—with more sophisticated economic techniques—should be conducted within Arkansas to evaluate further the existence of market power, the degree to which it is being exerted over broiler farmers, and how it affects prices for contract grower services.

Note: See endnote 2 for calculation details. Data on sales and number of employees per plant could not be obtained for four companies on this map: B&R Meat Processing, Key's Family Butcher Shop, and Natural State Processing.

Sources: USDA FSIS 2021; WattPoultry USA 2021; Wayne Farms LLC 2021; NETS Database 2020.

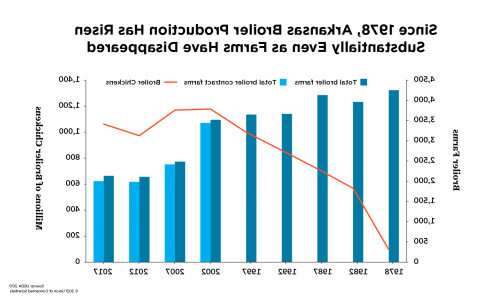

Arkansas’s Broiler Farms Have Gotten Bigger or Disappeared

As Arkansas’s poultry processing industry consolidated and became increasingly concentrated by big integrators such as Tyson, broiler farms consolidated or went out of business. Our analysis of USDA Census of Agriculture data on the number of broiler farms in the state from 1982 to 2017 indicated that the state has lost nearly 50 percent of its broiler farms since 1978 (Figure 3).1 While the number of broiler farms declined, the number of chickens produced for meat has dramatically increased in Arkansas (Figure 3).

These trends indicate that production has shifted to fewer, larger farms, which is consistent with national trends in broiler farming, driven in part by economies of scale, due to the increasing use of new technologies to raise chickens (MacDonald and McBride 2009). According to recent data, US broiler farmers in 1982, on average, raised 300,000 chickens annually. But by 2017 they raised more than double that number: 744,000 chickens annually (MacDonald 2020).

Broiler farms include those with an integrator processor contract. Ninety-seven percent of broiler farms nationally operate with a processor contract (MacDonald 2014), and in Arkansas, 94 percent of broiler farms reported having a processor contract, according to 2017 USDA Census of Agriculture data. In these agreements, broiler farmers are paid a predetermined base fee to care for and grow chickens from the time they hatch to the time they grow to slaughter weight. Meanwhile, the contracting processing company supplies the birds, feed, and technical advice for these operations (Tyson 2021). These contracts can be as short as one month or as long as five years (MacDonald 2014). When the birds are at the appropriate size for slaughtering and processing, farmers are offered a premium or discount on the base fee, reflecting their performance in production. This premium or discount is based on how many birds the farmers lost during production and the efficiency with which they converted feed to bird weight, relative to other farms that delivered birds to the processor during the same week (MacDonald 2014).

This consolidation could have one possible benefit for the largest broiler farms that are able to stay in business: theoretically, they could have slightly more power to negotiate contract prices with large poultry processors such as Tyson. However, our analysis reveals that in 2017 only 23 distinct companies processed broilers for just over 2,000 broiler farms in the state, indicating a power imbalance between processors and farmers. Further, smaller farms would have less power in markets dominated by both large farms and processors, putting at risk their ability to remain competitive in the Arkansas broiler production industry.

Source: USDA 2017.

Concentrated Broiler Farming’s Risks to Human Health

Large broiler farms, such as those that dominate the industry in Arkansas, raise chickens in densely confined settings, producing large quantities of dust and litter (chicken fecal matter). The dust contains small particles of feed, feces, and urine (Domingo et al. 2021). Litter produced by these chickens is mixed with feathers, spilled feed, and bedding material (such as hay), which must be stored in litter houses or piles outdoors, and be disposed of (MacDonald 2014). Broiler farmers give litter away or sell it to nearby crop farmers, who use it as fertilizer, since it contains plentiful amounts of nitrogen, a crucial nutrient for crop production (Imerman, Osenbaugh, and Imerman 2020).

These by-products have locally concentrated impacts on air quality and human health. Dust can negatively affect the air quality of surrounding communities (Domingo et al. 2021). Overuse or misapplication of chicken or other livestock manure as fertilizer on crop farms can have adverse consequences for both air and water quality. According to a 2021 study, air pollution from dust and manure produced by broiler farming in the United States is responsible for 1,300 excess deaths annually and is concentrated in communities where farms and processing plants are located (Domingo et al. 2021).

Litter storage and disposal also affects the health of communities where broiler farms operate. When stored outdoors, poultry litter and livestock manure can run off into nearby waterways, especially during heavy rainstorms or floods. As a result, nutrients such as nitrogen and phosphorus can adversely affect local water quality (Armstrong et al. 2010). Further, if livestock manure or chicken litter is overapplied or misapplied to cropland as fertilizer, it can more easily run off into nearby waterways or seep into groundwater.

Elevated nitrogen levels in both freshwater and marine systems disrupt their natural ecological balance, which can have negative consequences for nearby communities and even other food production industries (Boehm 2020b). Drinking water sourced from surface and groundwater contaminated by nitrogen compounds can be made safe to drink, but it is a costly process, and if some nitrogen compounds remain in the water, it can be harmful to human health, especially for infants and pregnant women (Boehm 2021). Currently, federal laws regulating how the largest animal production operations—referred to as confined animal feeding operations (CAFOs)—store and dispose of manure or litter lack enforcement mechanisms. As a consequence, manure or litter and their nutrients are more likely to enter waterways and harm the environment and people living near them (Miller and Muren 2019).

To demonstrate how much litter is produced, where it is produced, and how its production has become increasingly concentrated geographically over time in Arkansas, we multiplied 1982–2017 USDA Census of Agriculture data on the number of broiler chickens produced per Arkansas county per year by the amount of litter produced per broiler over its life (on average 47 days total, National Chicken Council 2020) to estimate total litter produced per county, per year (Boehm 2021; Porter and James 2020).

Our analysis found the following:

- In 2017 alone, Arkansas broiler farms generated 73.7 billion pounds of litter.

- Based on Tyson’s share of poultry processing sales statewide, its broiler farmers are responsible for 67 percent of this litter, or 49.6 billion pounds of litter.

- Worse, our analysis also revealed that because broiler farming and processing has concentrated in the state, so too has litter production. In 2017, a larger share of litter was generated in the northwest corner of the state, in Benton and Washington Counties, compared to that produced three decades ago (Figure 4). These two counties are home to a large share of the state’s Hispanic and Native American populations, according to US Census Bureau 2017 American Community Survey data on demographic characteristics of US counties (Figure 4).

Workers Endure Injury, Illness, and Low Wages

Approximately 31,000 workers serve as the backbone of the poultry slaughtering and processing industry in Arkansas and represent 10 percent of the industry’s 300,000 workers in the United States (Bureau of Labor Statistics 2018). Tyson, in particular, employs more than half of all meat processing plant workers in the United States and is one of the top three employers statewide (Ebner et al. 2016).

Before the rise of processing companies such as Tyson, whole chickens were slaughtered and shipped to grocery stores, where butchers would further process chickens for customers (Whittaker 2005). As the industry specialized due to economies of scale, processing companies grew larger. Consequently, so too did the plants where chickens are slaughtered and processed. Early on, the rise of companies such as Tyson in rural US states provided economic opportunities, including high-paying jobs for people who had been largely disconnected from the advancing US economy (Griffith 1995). But as the companies got larger and acquired economic and political power, and operations became much more specialized, conditions for workers began to deteriorate. Simultaneously, the industry began relying much more heavily on Hispanic immigrants for its workforce (Krumel Jr. 2017).

Today, US poultry processing plant workers are predominantly Black, Asian American, Pacific Islanders, and Latino. Many immigrated from Mexico and El Salvador (Stuesse and Dollar 2020). The presence of immigrants in this workforce has been found to allow companies to exert more control over their workers, since these workers are vulnerable due to their immigration status and because documented people of color may feel the need to shield themselves and their immigrant colleagues from law enforcement or other immigration enforcement authorities (Griffith 1995).

Poultry plant workers not only cut chicken into the products we eat, but they also unload chickens into the facilities and ensure the plants are clean and sanitary (Fremstad, Jin Rho, and Brown 2020; Kyeremateng-Amoah et al. 2014). Workers who slaughter and process chickens carry out repetitive cutting and cleaning tasks on a fast-moving assembly line in close proximity to one another (Taylor, Boulos, and Almond 2020). All these workers are exposed to many hazards while on the job, including musculoskeletal disorders, exposure to chemicals and pathogens, traumatic injuries from machines and tools, and stress from constant exposure to cold temperatures (CDC 2014).

According to 2019 data, nonfatal injury rates in the poultry processing industry were higher than in all other industries (Bureau of Labor Statistics 2019). While national data seem to indicate a downward trend in poultry plant worker injuries (Bureau of Labor Statistics 2019), the way the Occupational Health and Safety Administration (OSHA)—the federal agency responsible for enforcing health and safety protocols for workers—collects injury data from employers is problematic. Under current federal law, employers are required to report to OSHA only injuries or illnesses that forced workers to take days off from work (GAO 2016). This is problematic because musculoskeletal injuries, the most common injury type in this industry, do not always lead workers to take a day off (Xu, Strode, and Withers 2018). Also problematic is the fact that OSHA does not have a specific way for employers to record musculoskeletal injuries (Xu, Strode, and Withers 2018; GAO 2016).

The COVID-19 pandemic has made poultry plant jobs even more dangerous, since workers are in close proximity to each other and work in temperatures conducive to virus spread (Taylor, Boulos, and Almond 2020). Tyson and other companies have done little to protect their workers from the virus and, in some cases, intentionally deceived workers into returning to work without adequate COVID-19 protections (Boehm 2020b; Paschal and Zenteno 2020; Grabell and Yeung 2020).

OSHA has the authority to implement an emergency temporary standard to require employers to provide these workers with additional health and safety protections from COVID-19. While the agency implemented an emergency temporary standard for health care workers in the spring of 2020, it did not do so for meat and poultry plant workers, leaving them at heighted risk for infections, illness, and death.

Physical injury, illness, and death are not the only dangers these workers face on the job. In 2016, a survey of 500 poultry plant workers based in Arkansas found alarming levels of wage theft, racial and ethnic discrimination, gender-based harassment, retaliation, and lack of access to health insurance and earned sick leave (Ebner et al. 2016). There have also been reports of employees dying on the job because companies such as Tyson did not adequately implement OSHA requirements (DOJENRD 2009). Tyson in particular has violated health, safety, and wage laws at the state and federal levels hundreds of times since 2000 (Good Jobs First 2020).

Despite the dangers and risk of poultry processing jobs, wages for poultry plant workers have gone down, and workers’ incomes now stand just above the poverty line, all while industry profits have soared (Krumel Jr. 2017; Ebner et al. 2016; Southern Exposure 2021). Further, evidence indicates that the savings Tyson and other top poultry companies accrue from the reduced labor costs associated with a largely immigrant workforce are not passed on to consumers who purchase their products at grocery stores or in other food retail settings (Krumel Jr. 2017).

The high levels of consolidation we have observed in the poultry industry in Arkansas is likely one of the drivers of the dangerous working conditions, low wages, and lack of minimum benefits these workers currently encounter. Through consolidation, companies such as Tyson can acquire increased political power to influence federal or state policy. Additionally, as Figure 3 illustrates, few poultry processing companies exist per county in Arkansas. Assuming these workers cannot easily find employment in other types of work or cannot travel very far, they have few employer options and are less able to negotiate the terms of their employment.

This form of oligopsony power, which major processors such as Tyson have, has been shown to reduce workers’ ability to negotiate improved workplace conditions, wages, and benefits (Open Markets Institute 2021). Further, when few companies operate per county, they can more easily illegally coordinate with each other over the terms of employment for their workers. As noted earlier in this report, Tyson and other poultry processing companies have been accused of this type of illegal coordination over worker pay and have been sued as a consequence (Shanker and Mosendz 2019). Workers could gain more power in negotiating better working conditions and other benefits through unionization, which is what some groups are advocating in places such as Arkansas (Paschal 2021b).

Solutions That Protect Farmers, Workers, and Communities

Policies are needed to address the many issues arising from consolidation in Arkansas broiler farming and processing. While we focused our analyses on this one state, broiler farming and processing is concentrated in other states and communities as well. Consequently, policy solutions to many of the issues identified in this report should be national in scope to ensure these issues are resolved for all affected communities.

Toward this end, policymakers such as members of Congress, the USDA, and other federal agencies should take the following actions to address oligopsony and monopsony power in broiler markets:

-

Strengthen antitrust laws and enforcement.

- The Department of Justice and the Federal Trade Commission—which have the legal authority to scrutinize and regulate antitrust activity under the Sherman Antitrust Act of 1890 and the Clayton Antitrust Act of 1914—should evaluate market concentration, including in local agricultural supply chains such as the Arkansas poultry market.

- The USDA should revitalize its commitment and ability to ensure fair markets for all livestock producers, returning GIPSA to its previous status as a stand-alone agency. The secretary of agriculture should reverse the Trump administration’s decision to consolidate GIPSA into the Agricultural Marketing Service, allowing it to operate independently and in the interest of farmers and the public. Alternatively, Congress could establish a new agency within the USDA to maintain competitive agricultural markets. One recent proposal calls for an Independent Farmer Protection Bureau to assess competition issues in food and agriculture supply chains, including impacts on farmer profitability, the environment, and consumers (Willingham and Green 2019).

- Congress should oppose the “GIPSA rider” or similar amendments to annual agriculture appropriations legislation. For the past decade, the livestock industry has attempted—sometimes successfully—to attach an amendment that would limit the USDA’s ability to protect farmers’ basic rights and GIPSA’s ability to effectively enforce policies that promote competition.

- Congress should pass the Meat Packing Special Investigator Act (S. 2036), which would create an Office of the Special Investigator for Competition Matters within the USDA, improving the department’s ability to prevent and address anti-competitive practices in the meat and poultry industries.

- Congress should pursue other legislation that will protect farmers, workers, communities, and our environment by curbing uncompetitive markets and ending further consolidation in our food system.

-

Support small- and medium-scale poultry processors. As our analysis shows, the concentration of poultry production within Arkansas—driven in part by specialization in both production and processing, scale economies, and technological advancements—has deleterious consequences for communities. Proposed legislation such as the Strengthening Local Processing Act of 2021 (S. 370/H.R. 1258) supports small- and medium-sized meat and poultry processors, and the Agricultural Resilience Act (S. 1337/H.R. 2803) encourages more environmentally sustainable, diversified farming systems while also boosting funding for small-scale meat and poultry processing infrastructure. These alternative systems would give farmers other market opportunities and help curb the negative effects of consolidated and concentrated poultry processing.

-

Invest in the data needed to study concentration and competitiveness in poultry and livestock markets and supply chains. For much of the analyses in this report, we relied on the National Establishment Time Series (NETS) Database, a proprietary system developed and maintained by Walls & Associates for evaluating markets at the business and community levels (NETS Database 2020). Currently, federal data do not contain business-level information or the geographic specificity needed to accurately evaluate the level of consolidation in local food and agricultural markets. Federal data sources are also subject to protocols on the disclosure of data at the individual business level. The USDA, the US Census Bureau, and other federal statistical agencies should invest in making business-level data more readily available and accessible to researchers and decisionmakers. They should also reevaluate their protocols for determining whether business-level data can be publicly disclosed, perhaps by establishing a federal advisory committee composed of economists, scientists, statisticians, members of nongovernmental organizations, antitrust experts, and other stakeholders. More readily available data—like those contained in NETS—would increase the quantity of research on competition and concentration in the food and agriculture sector and other markets.

-

Shore up loopholes in Clean Water Act regulations regarding CAFO waste handling and disposal. Our analysis has shown that substantial quantities of chicken litter are produced in many Arkansas counties, which poses risks for air and water quality—and thus human health. We found that as the Arkansas broiler industry has consolidated, so too has the production of poultry litter, which is now highly concentrated in counties with large Hispanic and Native American populations. To address what may be an environmental justice issue in Arkansas, the Environmental Protection Agency needs to enforce Clean Water Act regulations more effectively, particularly with regard to how CAFOs store and dispose of chicken litter and other livestock waste.

-

Improve worker injury reporting requirements and insist on an emergency temporary standard. For years, nongovernmental organizations and the Government Accountability Office—the federal government’s primary watchdog over executive agency actions—have encouraged OSHA to improve the way worker injury data are reported. OSHA should require the reporting of injuries on the job even if workers do not have to take a day off, and there should be a specific system for reporting musculoskeletal injuries, given how common they are in the poultry processing industry. Further, due to poultry plant workers’ heightened risk of being exposed to COVID-19, OSHA should immediately issue an emergency temporary standard for their protection.

At the state level, Arkansas policymakers should do the following:

- Evaluate market power in Arkansas poultry markets. Our findings indicate substantial market concentration in the state, and the potential for market power to be exerted over farmers and workers. State policymakers should further evaluate these markets for competitiveness and ensure these groups are not suffering from the effects of market power.

- Enforce federal and state labor and wage laws. As noted earlier, Tyson and other top Arkansas poultry processing companies do not always follow labor and wage laws, risking the health, safety, and livelihoods of workers. The state legislature and relevant state authorities must do more to enforce existing laws, including increased penalties and fines for violations.

- Reduce worker discrimination and harassment. Existing state antidiscrimination laws should be enforced and other strategies should be employed to reduce discrimination and harassment toward these workers.

Highly consolidated agricultural markets—like those in the US broiler chicken industry—should be the exception, not the rule. The drivers of food system consolidation, including in broiler markets, are many and diverse, and cause many problems that have negative consequences for farmers, workers, and communities. Science-based, equitable solutions exist, and they can preserve profitability for farmers and poultry processing companies while better serving the public interest. As this analysis shows, Arkansas and federal policymakers must redouble their efforts to address consolidation in agricultural markets, to ensure that our food systems serve not just a few large, powerful companies, but all people and all communities.

Rebecca Boehm is an economist in the UCS Food & Environment Program.

Endnotes

1The Herfindahl-Hirschman Index (HHI) is the sum of squared market shares for each company in an industry or market. We calculated the annual HHI values from 1990 to 2017 using estimated sales data, a measure of company output, from the National Establishment Time Series (NETS) Database for companies classified as poultry processors, identified with the industry code 311615 in the North American Industry Classification System (NETS Database 2020). NETS sales data were available only through 2017 at the time this report was written.

2To estimate 2021 sales and sales shares per poultry processor operating in Arkansas by company, we multiplied the sum of NETS-estimated employees per company in Arkansas times the 2021 ratio of company sales to number of employees per company, as reported in Watt Poultry USA’s 2021 survey of top companies in the industry and from Wayne Farms LLC. (WATTPoultry USA 2021, Wayne Farms). Then we assigned these estimated sales values to each poultry processing plant currently operational in Arkansas, as identified in USDA’s 2021 Food Safety and Inspection Service Meat, Poultry and Egg Inspection Service Directory (USDA FSIS 2021). According to this directory, all companies with the exception of Tyson and Peco Foods operate just one plant in Arkansas, so we assigned all estimated sales for these companies to their single plant. For Tyson and Peco Foods, which operate 10 and 2 plants in the state, respectively, we divided total statewide sales across all plants per company in the state, and if needed, scaled sales for each plant based on their plant size as reported in the USDA FSIS directory. These scaling factors were only applied to Tyson plants. Non-integrator poultry processor NETS estimated sales for companies including B&R Meat Processing, Key’s Family Butcher Shop, and Natural State Processing were not available and are not reflected in these calculations or our calculation of total state poultry processing sales. However, these companies represent a small share of total sales in the state and likely would not appreciably affect our results.

Acknowledgments

This report was made possible through the support of UCS members.

For their thoughtful reviews and contributions, the author thanks Austin Frerick (Thurman Arnold Project, Yale University), Magaly Licolli (Venceremos), and three anonymous reviewers. At UCS, Charlotte Kirk Baer, Marcia DeLonge, Cynthia DeRocco, Sam Eley, Mike Lavender, Sarah Reinhardt, Kathleen Rest, Kyle Ann Sebastian, and Karen Perry Stillerman reviewed, refined, and provided critical and substantial feedback in the development of this report. The author also thanks Cynthia Williams of Style Sheets Editorial Services for her editing work.

Organizational affiliations are listed for identification purposes only. The opinions expressed herein do not necessarily reflect those of the organizations that funded the work or the individuals who reviewed it. The Union of Concerned Scientists bears sole responsibility for the report’s contents.

References

Antitrust Division. 2015. Price Fixing, Bid Rigging and Market Allocation Schemes. Washington, DC: Department of Justice. http://www.justice.gov/atr/price-fixing-bid-rigging-and-market-allocation-schemes.

Armstrong, Shalamar D., Douglas R. Smith, Phillip R. Owens, Brad Joern, and Candiss Williams. 2010. “Manure Spills and Remediation Methods to Improve Water Quality.” In Genetic Engineering, Biofertilisation, Soil Quality and Organic Farming, edited by E. Lichtfouse, 201–15. Dordrecht: Springer Netherlands. http://doi.org/10.1007/978-90-481-8741-6_7.

Boehm, Rebecca. 2020a. “With Trump Executive Order, Are Meat and Poultry Plants a COVID-19 Ticking Time Bomb?” The Equation (blog). May 20. http://blog.hr888888.com/rebecca-boehm/with-trump-executive-order-are-meat-and-poultry-plants-a-covid-19-ticking-time-bomb/.

Boehm, Rebecca. 2020b. Reviving the Dead Zone: Solutions to Benefit Both Gulf Coast Fishers and Midwest Farmers. Cambridge, MA: Union of Concerned Scientists. http://xk9.hr888888.com/resources/reviving-dead-zone.

Boehm, Rebecca. 2021. Dirty Water, Degraded Soil. Cambridge, MA: Union of Concerned Scientists. http://xk9.hr888888.com/resources/dirty-water-degraded-soil.

Boehm, Rebecca, Sean B. Cash, and Larissa S. Drescher. 2015. “Chapter 7: Food System Economics.” In Introduction to the U.S. Food System: Public Health, Environment, and Equity, first edition, edited by Roni Neff. San Francisco, CA: Jossey-Bass.

Budryk, Zack. 2020. “Tyson Foods Takes out Full-Page Ad: ‘The Food Supply Chain Is Breaking.’” The Hill, April 27, 2020. http://thehill.com/policy/healthcare/494772-tyson-foods-takes-out-full-page-ad-the-food-supply-chain-is-breaking.

Bureau of Competition. 2015. Competition Counts: How Consumers Win When Businesses Compete. Washington, DC: Federal Trade Commission. http://www.bulkorder.ftc.gov/system/files/publications/718a_competition_counts.pdf.

Bureau of Labor Statistics. 2018. “Quarterly Census of Employment and Wages.” Accessed February 1, 2021. http://www.bls.gov/cew/regional-resources.htm.

Bureau of Labor Statistics. 2019. "Occupational Injuries/Illnesses and Fatal Injuries Profiles." Accessed July 13, 2021. http://www.bls.gov/help/def/gqt_profile.htm.

CDC (Centers for Disease Control and Prevention). 2014. “National Institute for Occupational Safety and Health: Poultry Processing and Packaging.” Accessed July 13, 2021. http://www.cdc.gov/niosh/topics/poultry/process.html.

Charles, Dan. 2014. “The System Supplying America’s Chickens Pits Farmer vs. Farmer.” NPR, February 20, 2014. http://www.npr.org/sections/thesalt/2014/02/20/279040721/the-system-that-supplies-our-chickens-pits-farmer-against-farmer.

Congresswoman Chellie Pingree. 2020. “Pingree Introduces the Agriculture Resilience Act.” Press release, February 2020. http://pingree.house.gov/netzeroagriculture/agriculture-resilience-act.htm.

DOJENRD (Department of Justice Environment and Natural Resources Division). 2009. “Tyson Foods Pleads Guilty and Agrees to Pay Fine for OSHA Violation That Led to Worker Death.” Press release, January 6. http://www.justice.gov/opa/pr/tyson-foods-pleads-guilty-and-agrees-pay-fine-osha-violation-led-worker-death.

Domingo, Nina G. G., Srinidhi Balasubramanian, Sumil K. Thakrar, Michael A. Clark, Peter J. Adams, Julian D. Marshall, Nicholas Z. Muller, et al. 2021. “Air Quality—Related Health Damages of Food.” Proceedings of the National Academy of Sciences 118 (20). http://doi.org/10.1073/pnas.2013637118.

Ebner, Nina, Jessica Halpern-Finnerty, Saru Jayaraman, Miya Cain, Amber Moulton, and Chris Benner. 2016. Wages and Working Conditions in Arkansas Poultry Plants. Springdale: The Northwest Arkansas Workers’ Justice Center. http://www.uusc.org/report-wage-violations-poor-working-conditions-at-arkansas-poultry-plants/.

Ferguson, Rafter. 2021. Losing Ground: Farmland Consolidation and Threats to New Farmers, Black Farmers, and the Future of Farming.” Cambridge, MA: Union of Concerned Scientists. http://xk9.hr888888.com/resources/losing-ground.

Fortune. 2021. “Tyson Foods.” June 2, 2021. http://fortune.com/company/tyson-foods/fortune500/.

Frantz, Douglas. 1994. “How Tyson Became the Chicken King.” The New York Times, August 28, 1994. http://www.nytimes.com/1994/08/28/business/how-tyson-became-the-chicken-king.html.

Fremstad, Shawn, Hye Jin Rho, and Hayley Brown. 2020. Meatpacking Workers Are a Diverse Group Who Need Better Protections. Washington, DC: Center for Economic and Policy Research. http://cepr.net/meatpacking-workers-are-a-diverse-group-who-need-better-protections/.

Fritz, Sara. 1994. “Clinton Ties to Tyson Scion Still Drawing Critics' Fire: Politics: Some Allege Arkansan Got Special Treatment from Agriculture, Commerce Departments. He Denies It. Los Angeles Time, June 12, 1994. http://www.latimes.com/archives/la-xpm-1994-06-12-mn-3410-story.html.

FSIS (Food Safety and Inspection Service). 2021. “Meat, Poultry and Egg Product Inspection Directory.” Accessed February 1, 2021. http://www.fsis.usda.gov/inspection/establishments/meat-poultry-and-egg-product-inspection-directory.

GAO (Government Accountability Office). 2016. "Workplace Safety and Health: Additional Data Needed to Address Continued Hazards in the Meat and Poultry Industry." Accessed July 10, 2021. http://www.gao.gov/assets/gao-16-337.pdf

Good Jobs First. 2020. “Violation Tracker Parent Company Summary.” Accessed July 8, 2021. http://violationtracker.goodjobsfirst.org/parent/tyson-foods.

Grabell, Michael. 2015. “Tyson Foods’ Secret Recipe for Carving Up Workers’ Comp.” ProPublica, December 11, 2015. http://www.propublica.org/article/tyson-foods-secret-recipe-for-carving-up-workers-comp.

Grabell, Michael, and Bernice Yeung. 2020. “Emails Show the Meatpacking Industry Drafted an Executive Order to Keep Plants Open.” ProPublica. September 14, 2020. http://www.propublica.org/article/emails-show-the-meatpacking-industry-drafted-an-executive-order-to-keep-plants-open?token=I8mgMae53zU3XpjaqklAgwk_ytL5O1GN.

Griffith, D. 1995. “Hay Trabajo: Poultry Processing, Rural Industrialization, and the Latinization of Low-Wage Labor.” In Any Way You Cut It: Meat Processing and Small-Town America, edited by D. D. Stull, M. J. Broadway, and D. Griffith, 129–51. Lawrence: University Press of Kansas.

Hendrickson, Mary K. 2015. “Resilience in a Concentrated and Consolidated Food System.” Journal of Environmental Studies and Sciences 5 (3): 418–31. http://doi.org/10.1007/s13412-015-0292-2.

Hendrickson, Mary, William D. Heffernan, Philip H. Howard, and Judith B. Heffernan. 2001. “Consolidation in Food Retailing and Dairy.” British Food Journal 103 (10): 715–28. http://doi.org/10.1108/00070700110696742.

Hendrickson, Mary, Philip H. Howard, and Douglas Constance. 2017. Power, Food and Agriculture: Implications for Farmers, Consumers and Communities. SSRN Scholarly Paper ID 3066005. Rochester, NY: Social Science Research Network. http://papers.ssrn.com/abstract=3066005.

Hennigan, Mary, Abby Zimmardi, and Rachell Sanchez-Smith. 2021. “9,000 Employees Sick as COVID Overwhelms Arkansas Workplaces.” AP News, May 12, 2021. http://apnews.com/article/ar-state-wire-arkansas-philanthropy-health-coronavirus-pandemic-6f54f43a7f26cb34b70986a76a972160.

Imerman, Mark, Edward Osenbaugh, and Eric Imerman. 2020. Talkin’ Shit—Capturing the Value of Iowa Livestock Manure. Des Moines, IA: Regional Strategic Ltd. http://regionalstrategic.com/?creativo_portfolio=talkin-shit-capturing-the-value-of-iowa-livestock-manure.

Jacquemin, Alexis, and Margaret E. Slade. 1989. “Chapter 7 Cartels, Collusion, and Horizontal Merger.” In Handbook of Industrial Organization, volume 1, edited by R. Schmalensee and R. Willig, 415–73. Amsterdam: Elsevier. http://doi.org/10.1016/S1573-448X(89)01010-1.

Krumel Jr., Thomas P. 2017. “Anti-immigration Reform and Reductions in Welfare: Evidence from the Meatpacking Industry.” Choices 32 (1): 1–7.

Kyeremateng-Amoah, Emmanuel, Jackie Nowell, Aurora Lutty, Peter S. J. Lees, and Ellen K. Silbergeld. 2014. “Laceration Injuries and Infections among Workers in the Poultry Processing and Pork Meatpacking Industries.” American Journal of Industrial Medicine 57 (6): 669–82. http://doi.org/10.1002/ajim.22325.

Leonard, Mike. 2016. “Tyson, Perdue Face Chicken Broiler Price-Fixing Suit.” Bloomberg Law, September 6, 2016. http://news.bloomberglaw.com/class-action/tyson-perdue-face-chicken-broiler-price-fixing-suit.

Leonard, Mike. 2021. “Tyson Has 99 Million Dollar Deal with Consumers in Chicken Cartel Case.” Bloomberg Law, March 2, 2021. http://news.bloomberglaw.com/antitrust/tyson-has-99-million-deal-with-consumers-in-chicken-cartel-case.

Levy, Armando, and Tomislav Vukina. 2004. “The League Composition Effect in Tournaments with Heterogeneous Players: An Empirical Analysis of Broiler Contracts.” Journal of Labor Economics 22 (2): 353–77. http://doi.org/10.1086/381253.

MacDonald, James M. 2014. Technology, Organization, and Financial Performance in US Broiler Production. Washington, DC: Department of Agriculture Economic Research Service. http://www.ers.usda.gov/webdocs/publications/43869/48159_eib126.pdf?v=0.

MacDonald, James M. 2020. “USDA ERS—Consolidation in U.S. Agriculture Continues.” Amber Waves. February 3, 2020. http://www.ers.usda.gov/amber-waves/2020/february/consolidation-in-us-agriculture-continues/.

MacDonald, James M., and Nigel Key. 2012. "Market Power in Poultry Production Contracting? Evidence from a Farm Survey." Journal of Agricultural and Applied Economics 44, no. 4: 477–90.

MacDonald, James M., and William D. McBride. 2009. “The Transformation of US Livestock Agriculture: Scale, Efficiency, and Risks.” Economic Information Bulletin No. EIB-43. January 2009. http://www.ers.usda.gov/publications/pub-details/?pubid=44294.

Maraniss, David, and Michael Weisskopf. 1992. “In Arkansas, the Game Is Chicken.” Washington Post, March 22, 1992. http://www.washingtonpost.com/archive/politics/1992/03/22/in-arkansas-the-game-is-chicken/6244e0fa-5416-4a6a-bae8-a229b854ed98/.

Miller, D. Lee, and Gregory Muren. 2019. CAFOS: What We Don’t Know Is Hurting Us. 19-06-A. Washington, DC: Natural Resources Defense Council. http://www.nrdc.org/sites/default/files/cafos-dont-know-hurting-us-report.pdf.

Narayanan, Aparna. 2018. “Chicken McNuggets Supplier for McDonald’s Has Been Bought: Reports.” Investor’s Business Daily. August 17, 2018. http://www.investors.com/news/chicken-mcnuggets-mcdonalds-supplier-keystone-bought-tyson-foods/.

National Chicken Council. 2021 “US Broiler Performance: Average Days to Market Age.” Accessed August 2, 2021. http://www.nationalchickencouncil.org/about-the-industry/statistics/u-s-broiler-performance/

NETS Database (National Establishment Time Series Database). 2020. Utilizing Time Series Data to Understand Business Dynamics, 2017; accessed June 1, 2021. Denver, CO: Walls & Associates LLC.

NIMP and TCFI (National Institute on Money in Politics and The Campaign Finance Institute). 2021. Follow the Money Database. Accessed June 15, 2021. http://www.followthemoney.org/show-me?dt=1&s=AR&!y=1989,1988,1986&f-fc=1,2,3&d-eid=2670#%5B%7B1%7Cgro=.

NRDC (Natural Resources Defense Council). 2019. “New Drinking Water Report: Communities of Color More Likely to Suffer Drinking Water Violations for Years.” Press release, September 24. http://www.nrdc.org/media/2019/190924.

OCM (Organization for Competitive Markets). 2016. “Packers and Stockyards Act Reform.” Accessed June 30, 2021. http://competitivemarkets.com/gipsa/.

OCM (Organization for Competitive Markets). 2018. “GIPSA Is Dead; the Fight for Producer Protections Continues.” Accessed June 30, 2021. http://competitivemarkets.com/gipsa-is-dead-the-fight-for-producer-protections-continues/.

Ollinger, Michael, James M. MacDonald, and Milton Madison. 2000. “Structural Change in US Chicken and Turkey Slaughter.” US Department of Agriculture Economic Research Service, November 2000.

Ollinger, Michael, James, M. MacDonald, and Milton Madison. 2005. “Technological Change and Economies of Scale in US Poultry Processing.” American Journal of Agricultural Economics 87 (1): 116–29.

Open Markets Institute. 2021. "Anti-Monopoly Basics: Workers and Monopoly." Accessed July 13, 2021. http://www.openmarketsinstitute.org/learn/workers-monopoly.

Packers and Stockyard Program. 2019. Annual Report. Washington, DC: Department of Agriculture Agricultural Marketing Service. http://www.ams.usda.gov/reports/psd-annual-reports.

Paschal, Olivia. 2021a. “Emails Show Tyson’s Sway over Arkansas Mayor during COVID Surge in Plants.” Facing South, February 5, 2021. http://www.facingsouth.org/2021/02/emails-show-tysons-sway-over-arkansas-mayor-during-covid-surge-plants.

Paschal, Olivia. 2021b. "For Magaly Licolli, Organizing Poultry Workers Starts with Learning Together." Facing South, June 1, 2021. http://www.facingsouth.org/2021/06/magaly-licolli-organizing-poultry-workers-starts-learning-together.

Paschal, Olivia, and Rolando Zenteno. 2020. “Workers Say Arkansas’ Poultry Giants Aren’t Protecting Them from COVID-19.” Facing South, April 28, 2020. http://www.facingsouth.org/2020/04/workers-say-arkansas-poultry-giants-arent-protecting-them-covid-19.

Porter, Sarah A., and David E. James. 2020. “Using a Spatially Explicit Approach to Assess the Contribution of Livestock Manure to Minnesota’s Agricultural Nitrogen Budget.” Agronomy 10 (4): 480. http://doi.org/10.3390/agronomy10040480.

S&P Global. 2021. “Capital IQ Data.” Accessed July 1, 2021. www.capitaliq.com.

Saitone, Tina L., and Richard J. Sexton. 2017. Concentration and Consolidation in the U.S. Food Supply Chain: The Latest Evidence and Implications for Consumers, Farmers, and Policymakers. Kansas City, MO: Federal Reserve Bank of Kansas City. http://www.kansascityfed.org/documents/7184/si17102.pdf.

Sexton, Richard J., and Tian Xia. 2018. “Increasing Concentration in the Agricultural Supply Chain: Implications for Market Power and Sector Performance.” Annual Review of Resource Economics 10 (1): 229–51. http://doi.org/10.1146/annurev-resource-100517-023312.

Shanker, Deena, and Polly Mosendz. 2019. “America’s Chicken Industry Accused of Conspiring to Keep Immigrant Wages Down.” Bloomberg, September 3, 2019. http://www.bloomberg.com/news/articles/2019-09-03/biggest-chicken-processors-accused-of-immigrant-wage-plot.

Shroeter, John, and Azzeddine Azzam. 1990. "Measuring Market Power in Multi-product Oligopolies: The US Meat Industry." Applied Economics 22, no. 10: 1365–76. http://doi.org/10.1080/00036849000000107.

Southern Exposure. 2021. “From the Archives: Chicken Empires.” Facing South, June 1, 2021. http://www.facingsouth.org/2021/06/archives-chicken-empires.

Stuesse, Angela, and Nathan T. Dollar. 2020. “Who Are America’s Meat and Poultry Workers?” Working Economics Blog. September 24, 2020. http://www.epi.org/blog/meat-and-poultry-worker-demographics/.

Taylor, Charles A., Christopher Boulos, and Douglas Almond. 2020. "Livestock Plants and COVID-19 Transmission." Proceedings of the National Academy of Sciences 117, no. 50: 31706–15. http://doi.org/10.1073/pnas.2010115117.

Tessum, Christopher W., David A. Paolella, Sarah E. Chambliss, Joshua S. Apte, Jason D. Hill, and Julian D. Marshall. 2021. “PM2.5 Polluters Disproportionately and Systemically Affect People of Color in the United States.” Science Advances 7 (18): eabf4491. http://doi.org/10.1126/sciadv.abf4491.

Tyson. 2018. “Tyson Foods Major Locations.” Accessed May 1, 2021. http://www.tysonfoods.com/sites/default/files/2018-07/Tyson%20Foods%20Major%20Locations.pdf.

Tyson. 2019. “Tyson Foods Facts.” Accessed May 1, 2021. http://ir.tyson.com/about-tyson/facts/default.aspx.

Tyson. 2021. “Contract Poultry Farming.” Accessed May 1, 2021. http://www.farmwithtyson.com/overview-of-contract-poultry-farming/.

Tyson. n.d. “Annual Reports.” Accessed May 1, 2021. http://ir.tyson.com/reports/annual-reports/default.aspx.

US Census Bureau. 2017a. “American Community Survey.” Accessed May 4, 2021. http://www.census.gov/programs-surveys/acs.

US Census Bureau. 2017b. “Economic Census.” Accessed April 2, 2021. http://www.census.gov/programs-surveys/economic-census.html.

USDA (US Department of Agriculture). 2017. “Census of Agriculture: 2017 Census Volume 1, Chapter 1: U.S. National Level Data.” Accessed April 1, 2021. http://www.nass.usda.gov/Publications/AgCensus/2017/Full_Report/Volume_1,_Chapter_1_US/.

USFTC (US Federal Trade Commission). 2013. “Price Fixing.” Accessed July 12, 2021. http://www.ftc.gov/tips-advice/competition-guidance/guide-antitrust-laws/dealings-competitors/price-fixing.

WATTPoultry USA. 2021. “Top Broiler Company Profiles.” WATT Global Media 22, no. 3 (March). http://www.wattpoultryusa-digital.com/wattpoultryusa/library/.

Wayne Farms LLC. 2021. “Danville, AR Plant Fact Sheet” Wayne Farms LLC. Accessed August 2, 2021. http://waynefarms.com/wayne-farms-locations/item/danville-ar

Whittaker, William G. 2005. Labor Practices in the Meat Packing and Poultry Processing Industry: An Overview. Washington, DC: Congressional Research Service.

Willingham, Zoe, and Andy Green. 2019. “A Fair Deal for Farmers: Raising Earnings and Rebalancing Power in Rural America.” Center for American Progress. May 7, 2019. http://www.americanprogress.org/issues/economy/reports/2019/05/07/469385/fair-deal-farmers/.

Xu, Huiqi, Maureen Strode, and Andrew Withers. 2018. "Injuries at Poultry Processing Plants Often Underreported." Associated Press and the Midwest Center for Investigative Reporting, July 15, 2018. http://apnews.com/article/b247a4f0cf234ce88658506209bfac0e.